Reference Projects

We are proud that our satisfied customers have agreed to the publication of our joint success stories. The diverse needs our users express are opportunities for us to demonstrate our expertise in different market contexts, including public, industrial and private construction projects as well. The menu entries below offer an overview of our past projects.

Test surface

Test surface in Nagykerek

August 2018

Test surfaces for our installation and statics design guides have been prepared in August 2018. For incorporation a 12-tonne combination roller, a 3-tonne footpath roller and vibratory plates of different sizes were used. The purpose of the measurements was to gather and provide architects and developers with all the necessary information.

Industrial floors

Hungaropharma Zrt. Storage Hall Extension in Debrecen

November 2018

Apart from the thermal insulation performance,

compliance with the relevant static requirements was also an important aspect

of the layer structure. The aim was to construct the following layer structure,

that is suitable for the loads imposed by rack feet and forklifts:

Advantages:

The load-bearing capacity of the floor built in this manner is higher than in applications with boarded insulation. This way there is no need to additionally reinforce the floor, because the use of plastic or steel fiber is enough. The coarse-grained bedding layer of 15 cm built on the foam glass can fulfill this way several functions. First, this protects mechanically the foam glass layer against the loads and mechanic impacts caused by circulation during construction works; second, it increases the load-bearing capacity of the foam glass layer; third, it reduces the stress generated by the floor loads and transmitted to the foam glass layer.

Further

advantages of the bedding layer structured in this manner: there is no need to

additionally reinforce the floor, because the use of plastic or steel fiber is

enough, and the use of a concrete pump is also unnecessary.

Thermal Insulation Under an Industrial Hall Floor in Ócsa

November 2018

The Energocell® foam glass granules were used for the thermal insulation under the floor of an industrial hall of 2200 m², developed by HORAÉP Kft. for Eurochamp Hungária Kft. (the investor). The 35 cm thick loose granule layer resulted in a 25-cm layer after compaction at 1:1.4, on which 20 cm of stone rubble was placed, to reach the adequate load-bearing capacity. The stone rubble also protects mechanically the foam glass, therefore circulation with heavier vehicles (concrete mixer) during construction is allowed on the bedding, and the use of a concrete pump can be avoided.

The Energocell® foam glass granules were compacted with a road roller on the larger continuous surfaces, and with a vibratory plate near the service installation pipes.

Perimeter Insulation of the New Storage Hall of Globiz International Kft. in Debrecen

May 2018

The most recent application of Energocell® as perimeter thermal insulation of the floor was executed at a storage hall in Debrecen by Fémszerkezet Kft. The foam glass granules were incorporated in a 1.5-m strip along the outlines of the building. The thermal insulation of high load-bearing capacity was compacted with a vibratory plate of 100 kg in a 30 cm thick layer.

Agricultural hall with a 3,300 m² floor area near Debrecen

November 2017

Due to the function of the building the thorough thermal insulation of the floor was essential. For this a 30-cm compacted layer of Energocell® was incorporated. The final layer-thickness was reached by spreading and compacting 2 layers of cellular glass. Ducts and wiring for the technical equipment of the hall were laid in the compacted soil layer, before the spreading of the Energocell®. Because of the closely-spaced building service installations infrastructure only a smaller roller proved suited. Therefore a 3 tonne double-drum vibratory roller was used for this purpose.

With this technology the execution time of the thermal insulation layer was significantly reduced. Additionally, the Energocell® layer replaced not only the boarded insulation materials, but some of the filling material too.

Test Surface for Industrial Hall

October 2017

Place of execution: Debrecen, Vezér u.

Date of execution: 13.10.2017

Developer: Grabarics Kft.

Type of roller: 12,1 tonne vibratory smooth drum roller, Caterpillar CS563E

The test surface was executed with the purpose to provide information regarding the maximum loading capacity of an Energocell® foam glass insulation layer compacted at a 1:1.3 rate.

Under the foam glass a compacted layer of concrete chips of 160 N/mm² was placed. The highly compact surface made unnecessary the use of any geotextile fabric for separation.

The granules were compacted in two layers. The thickness of each loose layer was 20 cm, that shrinked to 15 cm after compaction. This is how the finished layer-thickness of 30 cm was reached.

For the spreading of the material a JCB excavator was used. Compaction was carried out with the above presented (also see the pictures) vibratory roller, by rolling with no vibrations.

The plate-load testing results (E2= 94 N/mm²!) are detailed in the annexed measurement report.

Further observations:

Rubber-tyred machines (e. g. front-end loader etc.) did not leave any trace on the compacted layer, but the 24-tonne dumper loaded with stone chips caused the loosening of the granules while traversing, especially when cornering. Therefore, it is very likely that mixer shouldn't circulate either on the compacted foam glass layer - and a concrete pump may be necessary for the execution of industrial floors.

Building with strip foundation

Single-family Home in Horvátzsidány

October 2018

Our buyer from Horvátzsidány had no doubt that he would use Energocell® foam glass granules for the thermal insulation under the floor of their family home under construction. The 30-cm thick Energocell® foam glass granule layer was placed between the foundation strips, on the thoroughly compacted soil covered with geotextile for separation. Then it was compacted with a 90-kg vibratory plate compactor for optimal thermal insulation and load-bearing capacity. On this compacted surface the PE film and the reinforced concrete was then laid.

Building in Nagyvárad

June 2018

The Energocell® foam glass granules were incorporated under the basement rooms of the building. The foam glass granules were compacted into a 30 cm thick layer under the concrete blinding layer.

Single-family Home in Harka

June 2018

The Energocell® foam glass granules were used in a thermally insulative layer between the strip foundations. The 25 cm thick compacted layer provides excellent thermal insulation, and also serves as a bedding layer.

Single-family Home in Szombathely

May 2018

The Energocell® foam glass granules were used in a thermally insulative layer between the strip foundations. The 30 cm thick compacted layer provides excellent thermal insulation. Because of the increased amount of fill needed, a layer of gravel was incorporated under the foam glass.

Two-storeyed Single-family Home in Miskolctapolca

October 2017

The two-storeyed family home was executed with combined foundation. Due to the sloping of the site the reinforced concrete base slab was complemented by a strip foundation under one part of the building. The building was provided with excellent thermal insulation by a 40 to 50 cm compacted Energocell® layer placed under the reinforced concrete slab.

Low energy house in Szeged

August 2017

This low energy single-family home was built in the suburbs of Szeged using combined foundation methods. Given the ground conditions, a strip foundation was executed under the outer walls of the building, with cast-in-place reinforced concrete footing on which a concrete slab was placed.

The thermal insulation of the floor was further improved by incorporating Energocell granules not just under the reinforced concrete slab but also around the interior sides of the strip foundation, in a 30-40 cm thick layer that reaches down to the lower plane of the foundation. The thermal insulation of the floor is provided by an Energocell foam glass layer of 30-cm finished layer-thickness.

Lightweight House in Piliscsaba

July 2017

This lightweight building with combined foundation was built in Piliscsaba. On the Energocell® foam glass granule layer of 30 cm loosely filled between the footing walls a flooring with wooden structure was installed. The thermal insulation under the foundation raft is provided by a compacted foam glass layer of 20-cm finished layer-thickness.

Single-family Home in Sopron

This single-family home was built in the suburbs of Sopron. To thermally insulate the floor the foam glass granules were compacted and built in the reinforced concrete footing. The Energocell® foam glass granules were incorporated as a 30-cm compacted layer. Due to the big bag packaging the foam glass granules were easily and quickly unloaded by a crane truck to the place of incorporation.

Single-family Home in Debrecen

March 2017

This

single-family home was built in the city centre of Debrecen. The

continuous building line (along the street) allowed for building a well

foundation with beam grid footing. Foam glass granules were compacted and built in the beam grid footing to thermally

insulate the floor. Another

advantage of the technology is that it does not increase the building's

height, because the insulation is installed under the blind concrete.

Building with raft foundation

Merkbau Paper Mill in Mórahalom

June 2018

At the beginning of summer in 2018 the paper mill in Mórahalom was developed, and the foam glass granules were built in its structure. The foam glass granule layer of 25-cm initial thickness reached the 61 MPa load-bearing capacity after compaction by 30%, and infilling with fine fractions. The developers at Merkbau used a footpath roller for incorporation.

Single-family Home in Vecsés

May 2017

Under the raft foundation of this single-family home we built in a 30 cm thick compacted layer of Energocell® foam glass granules. By this method the load-bearing bedding and the subfloor insulation of the building was replaced by one layer of granules. Therefore, the substructure works were simplified and the execution time was also reduced.

Low energy house in Buda

March 2017

We delivered our first foam glass shipment to Buda on the 10th of March 2017, for it to be used as insulation under the raft foundation of a single-family house. The goal of the family was to build a low energy home, and the Energocell® foam glass granules proved to be the perfect choice. A total amount of 95m³ of 10/60 size granules was incorporated under the house by using a 200-kg manual vibratory plate compactor.

The foundation works of the nearly 150 m² house began with the excavation of the building pit for the bedding layer. Due to the sloping of the plot at the back of the house propping with masonry blocks was necessary. At the next stage, the infrastructure for building service installations was integrated. Then the lining of the building pit followed with a 200g/m² geotextile sheet, allowing an additional 50-cm edge to overlap beyond the pit margins. After finishing the preparation works the placing of the foam glass began. To obtain the appropriate strength and thermal insulation values we placed the foam glass in three layers, compacted to a degree of 30%. The combined thickness of the layers reached 45 cm, providing a suitably strong bedding for the building, and also an appropriate insulation under the raft foundation.

Building with Basement

Passive house

Eco-passive House

August 2017

The

company that built this single-family home at the periphery of Cluj-Napoca

exclusively plans and executes eco-passive houses that are certified by an

international body. Since environmental

consciousness and good thermal insulation properties were important material

selection criteria, they chose the Energocell®

foam glass granules for the

thermal insulation of the foundation and the floor. The

building's foundation was executed as a well foundation on which a reinforced

concrete beam grid was placed. To

provide a foundation insulation that is free of thermal bridging, the bottom

and vertical sides of the beam grid were enclosed with foam glass granules. Under the

reinforced concrete slab, a 50-cm thermal insulation layer of compacted foam glass granules was incorporated.

Earth house, dome house

Construction Works of a Dome House in Nyúl

July 2018

At this point the underground level of stage 1. can be seen. In some places the excavation of fertile soil exceeded 3 meters in depth, to reach under ground level. On this level a strip foundation was executed and filled with granules in a 23-cm compacted layer. The granules were placed on the undisturbed soil. On this layer a 12 cm thick reinforced concrete slab was placed, followed by the waterproofing insulation and a 6 cm thick blind concrete.

An interesting feature of the structure is that between the reinforced concrete slab and the blind concrete no thermal insulation has been placed, since this is solved with the foam glass installed underneath. Using this method, according to the architect, a so-called "thermal storage" will be created, because the thicker the concrete, the slower it grows cool.

Stage 2. is scheduled in September, when

the thermal insulation of the ground floor will be executed, followed by the

external vertical insulation of the walls in the spring of 2019.

Lightweight filling

Intermediate Floor Filling at the Ferenc Puskás Stadium

August 2018

At the Ferenc Puskás Stadium, on a more than 7,000 m² surface, the Energocell® granules were used as filling in the layer housing the utility installations. The architects have chosen the Energocell® foam glass because its water absorption capacity is very low - due to its closed-cell structure -, and the particles allow vapour-permeation, therefore in the event of pipe bursts or leakages the water would not become stale in the layer. The incorporated foam glass layers were 14-16 cm thick under the plumbing units, and 30 cm thick in other places. Given that the service installation pipes were laid in the foam glass layer, the use of hand rollers proved to be the most practical method for incorporation.

Building renovation

Floor Refurbishment Works in the Sándor-Metternich Castle in Bajna

October 2018

In September 2018, as part of the national castle and palace renovation program, the restoration of the Sándor-Metternich Castle in Bajna has been launched, and it also became the first historical building renovation project of Energocell® in which the foam glass granules were used as filling material of the vaulted ceiling. The developer chose the Energocell® granules over other filling materials, because of their light specific weight (150-175 kg/m³) and cost-efficiency. The vaults required a 15-70-cm foam glass layer, that was incorporated and compacted by 10% with a 50-kg grass roller. As seen in the pictures, covering of the surface with OSB boards is recommended to facilitate circulation.

Floor Refurbishment in the Károlyi-Csekonics Palace

July 2018

The following reference pictures were taken during the refurbishment works of the Károlyi-Csekonics Palace. At underground level the complete floor surface needed levelling and thermal insulation using 20 cm and sporadically 30 cm of Energocell® foam glass granules. The underground ventilation ducts that stick up in several places, have also been enclosed with Energocell®.

The 110 water-pipes can be easily laid in the foam glass layer, and do not require any fixing either. The technicians picked up the granules on the route of the pipelines, established the slopings, then filled back and compacted the foam glass. Execution was fast, practical and functional.

Floor Refurbishment in a Residential Building in Debrecen

April 2018

The refurbishment consisted of the breaking up of the concrete base course and the removal of the original filling, after which a 20 cm thick layer of compacted Energocell® was incorporated in the building pit linned with geotextile. The compacted foam glass was covered then with a PE membrane on which an underfloor heating system film was placed. On the film a welded mesh was placed, on which the underfloor heating tubes were installed. The floor layered in this manner is significantly simpler than the conventional structure, therefore the execution time decreased substantially.

Residential Building Refurbishment in Szentes

November 2017

The Energocell® cellular glass granules are ideal for floor refurbishing in old buildings. Floors in old buildings are typically installed on sand or blast-furnace slag layers. Obviously, this no longer complies with current thermal requirements. Therefore, by removing the old filling material and replacing it with cellular glass granules a floor structure that satisfies current requirements was built.

Another advantage would be that Energocell® can be used in renovations of historical buildings as well, because it forms a thermally insulative and vapour-permeable layer structure. If the cellular glass granules layer is not enclosed with concrete or other waterproofing materials, the structure remains vapour-permeable.

Road construction

Truck Reception Area

June 2017

The truck reception area was executed with paving stone covering. This proved problematic because of the low load-capacity of the ground. Energocell® foam glass granules of 200 kg/m³ loose bulk density were distributed as a bedding layer. The material was compacted in two layers with different thicknesses (ranging from 28 to 23 cm). Above and under the foam glass layer geotextile sheets of 200g/m² were laid. The bottom geotextile sheet prevents the mixing of the foam glass with the soil, and the top geotextile sheet prevents the washing in of the fine fractions from under the paving - in time this might lead to the settlement of the pavement. The blanket course of fine fractions was distributed on the top geotextile layer, and 10 cm thick paving stones were embedded in it.

Storage Tank Insulation

Subsequent thermal insulation of a 250-m³ storage tank with Energocell® foam glass granules

The 250-m³ storage tanks of an Eastern

Hungarian food manufacturing plant needed retrofitting with thermal

insulation. The industrial tank of 26-m² area and

250-m³ capacity (~10-m clear height) imposes a 13-t/m² load on the new bottom

plate. Due to the high

loads only highly resistant - non-shrinking - thermal insulation could be

used, that needed to be heat resistant as well to withstand the welding of

the bottom metal plates. The Energocell® foam glass granules fully

satisfied the listed criteria.

The building of the new bottom plate

started with a collar made of metal plates and fitted with ribs for support. Then the foam glass was placed and

compacted to a 18-19 cm thick layer. The foam glass granules were shoveled into the tank

through a side opening.

Compaction along the collar was executed with hand-operated compaction tools, because of the space limitations and to protect the collar; but on the larger continuous surfaces electrical vibratory plates were used (because of the enclosed space). The applied compaction rate was 1:1.3, and the final 18-19 cm thick layer resulted from a 23-25-cm layer of loosely spread material. Granules of 10-60 mm fraction size, and fine granules of 4-8 mm were placed and compacted on this layer, to include them between the larger granules, and to level the surface - preparing it for the very high 13-tonne/m² load and the metal plating.

The 18-19-cm compacted Energocell® foam glass granule layer was then covered with 5 mm thick metal plates that were joined by continuous weld at their faying surfaces (on the photo only the temporary joins are visible).

Swimming pool

Swimming Pool Insulation in Timişoara

December 2018

Thermal insulation at the base and walls of a hot water swimming pool is recommended for the reduction of operating costs. The Energocell® thermally insulative foam glass is an ideal solution for this purpose as well, due to its high load-bearing and thermal insulation capacity.

Swimming Pool Construction Near Oradea (Săldăbagiu de Munte)

May 2018

This time the Energocell® granules were placed under a cast-in-place reinforced concrete pool. In this project the foam glass granules were used mainly for their static stability improving properties. The foam glass was compacted in several layers, separated by a PE membrane on which the concrete blinding layer was placed, followed by the execution of the pool structure.

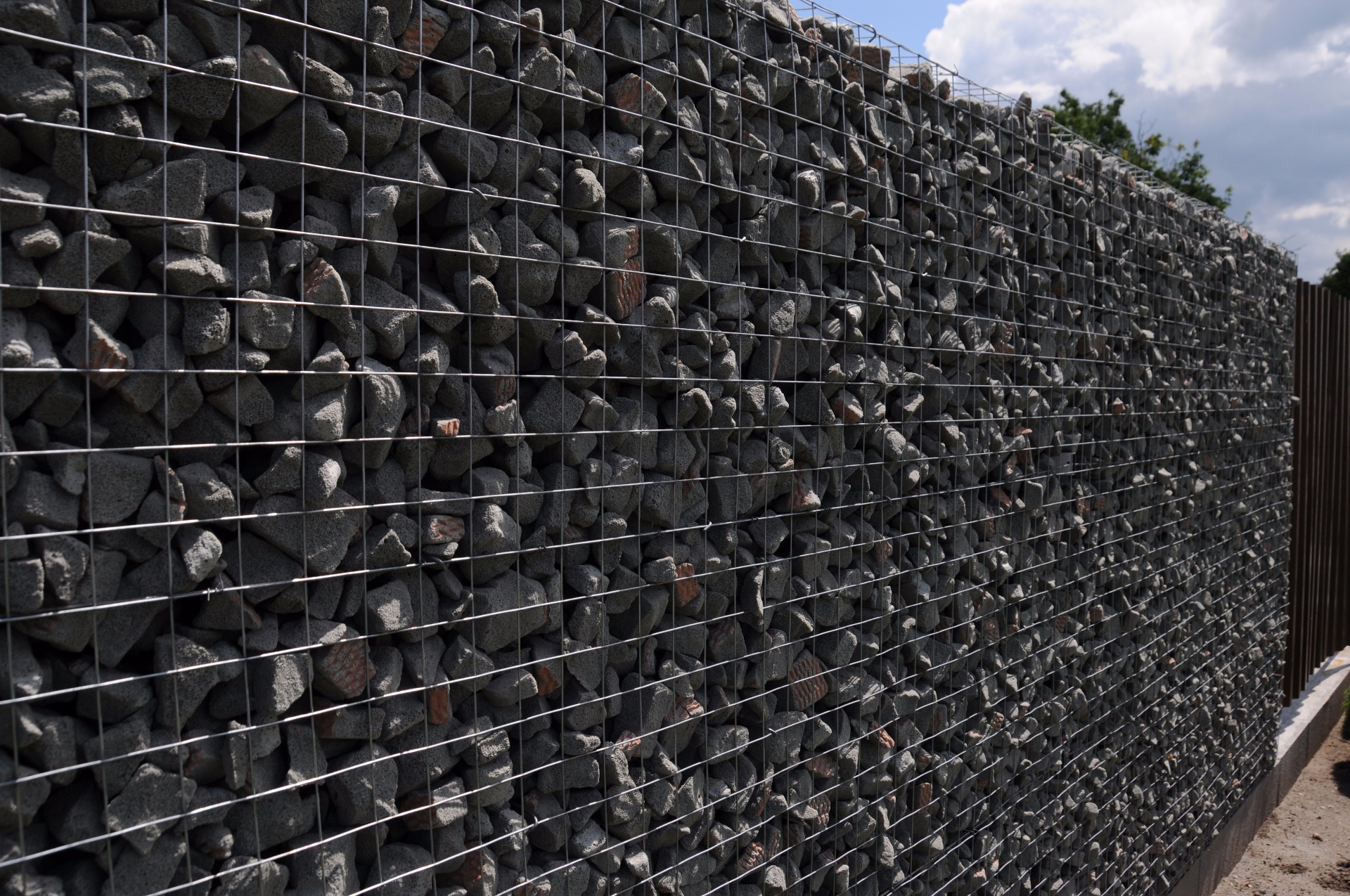

Gabion wall

Sound-absorbing Wall in Debrecen

January 2018

The main purpose of this sound-absorbing gabion wall is the separation of the manufacturing plant from the neighbouring residential area. Its role is to block out the operational noise. The steel structure is 4 m high and 40 cm thick. The height of the footing is 40 cm on average.

- The wire

fencing panels were of 5 mm wire thickness and with 5x5 cm aperture size.

- The

centre-to-centre distance of the supporting structure spacing is 1.970 mm.

- Braced

grider measurements:

main grider: 60 x 80 x 3 mm hollow section;

bracing: 40 x 40 x 2 mm hollow section. - Surface

treatment: subsequent hot-dip galvanizing.

The

sound-absorbing gabion wall was executed in stepped disposition adapted to

the slope of the terrain.

Gabion Wall in Albertirsa

June 2017

The fence built serves as a boundary between two plots. The foam glass filled gabion cages and the imitation wood surface-treated trapezoidal sheet panels were placed alternately. Given that the weight of the fence executed in this manner is just a fraction of that of the stone filled gabion fences, the foundation works are also executed with lower costs. The gabion cages and fence panels were fixed to steel profiles with hollow structural section. The foam glass granules were filled between 5 x 5 cm animal wire meshes, which is also a cost-efficient solution.